|

|

WEATHER PROOF & FLAME

PROOF HEAD TYPE THERMOCOUPLES & RTD SENSORS

|

PLASTECH make Thermocouples are widely used in

various industries as Temperature Sensing Elements. They

are important element of dependable Temperature

measurement.

PLASTECH make thermocouple assemblies for

practically every application covering R & D

requirements to furnace temperature. Our services are

also available to design and fabricate special purpose

thermocouple assemblies as per customer's design and

specifications.

Types of thermocouples available are 'J'

(Iron-Constantan),

T (Copper-Constantan), K (Chormel - Alumel), S (Pt/Pt-Rh

10%),

R (Pt/Pt-Rh 13%) & etc.

RESISTANCE TEMPERATURE DETECTORS (RTD) :-

PLASTECH make RTD employs high purity electrical

resistance wire, non - inductively wound on ceramic or

glass base material. When RTD element subjected to heat

it changes its electrical resistance value corresponding

to variation in temp. and thermal coefficient. The most

commonly used resistance element is platinum known as

PT-100 (100 ohms at 0oC). The RTD characteristics have a

standard pattern for different resistance elements like

Copper, Nickel, Platinum etc.

THERMOCOUPLE (T/C) :-

PLASTECH make thermocouple employs two dissimilar

metals. When two dissimilar metals welded together at

one end subjected to heat, it develops a small DC

voltage (EMF) corresponding to temperature difference

between hot junction (measuring) and cold junction

(reference). The temperature EMF characteristics have

standard pattern for different type of thermocouple

element like

T, J, K, R, S, etc.

MINERAL INSULATED ELEMENT (MI) :-

PLASTECH make mineral insulated (MI) sensors are

insulated with tightly compacted magnesium oxide powder

enclosed in various metal sheaths. Hot junction is

formed in inert gas atmosphere and tested for leakage

with Nitrogen gas under pressure. The MI sensors can be

given from few inches to several meters. Sheath can be

bend, twisted and flattened to suit application. The

junction can be Ground or Ungrounded.

THERMOCOUPLE & RTD's WITH TRANSMITTER :-

Temperature transmitter in head mounting isolated /

non-isolated / intrinsically safe type for RTD and

Thermocouple.

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

| |

|

SPECIFICATION |

|

Standard Element : |

T, J,

K, R, S, RTD - Simplex or Duplex (2 wire or 3 wire) |

|

Enclosure : |

Stainless Steel, Die cast Aluminum and bakelite with

cable entry. |

|

Protection : |

IP 55,

65, 67, Flame proof Gr I, IIA & IIB. |

|

Sheath size : |

1 mm to

25 mm OD to any length. |

|

Terminal : |

Brass /

Stainless steel connectors, Spring loaded terminal block

if required and Colour codes for different type of

Thermocouple. |

|

Fittings : |

Fix /

Adjustable gland, compression fittings, Flang or spring

loaded

bionet with adopter. |

|

THERMOCOUPLE FOR

PLASTIC / RUBBER & PHARMACEUTICAL INDUSTRY |

| |

|

|

|

|

Type : |

"J"

(Iron-Constantan), "K" (Chormel-Alumel),

"T" (Copper-Constantan), "S" (Pt/Pt-Rh 10%),

"R" (Pt/Pt-Rh 13%), And all other STD Types. |

|

Application : |

All types of

Hydraulic, Injection, Boiler, Compression, Blow Moulding Machines.

Suitable for measuring Temperature at

Cross heads, die and barrel. |

|

Model : |

Spring loaded Bionet,

rotating holder, rotating spring,

transition joint, bend & Screw Type etc.

|

|

Size : |

All Standard Sizes. |

|

|

|

|

|

|

|

|

|

|

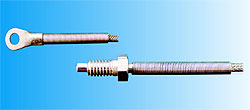

WASER / BOLT

THERMOCOUPLE |

|

|

|

|

|

|

Size : |

M4, M5, M6, or 1/8",

5/32", 3/16", 1/4" and as per requirement.

1. Suitable for Surface Temperature measurement.

2. Easy to install. |

|

Type :

|

All Standard Types |

| |

|

|

|

|

|

|

|

|

|

|

|

PROBES FOR

PORTABLE TEMPERATURE INDICATORS |

|

|

|

|

|

|

Type : |

All Standard Types |

|

Model : |

Immersion probe,

Pointed probe. Quick response MI Immersion Probe.

Quick connection & dis-connection

Probe

Surface Probe.

Prick Probe.

Air / Gas Probe. |

| |

|

|

|

|

|

|

|

|

|

|

|

THERMOWELLS |

|

WELDED AND BAR STOCK AS

PER REQUIREMENTS |

|

|

|

|

|

A wide range of Thermowells

for almost all temperature sensing requirements in high

and low temperature, high pressure, high velocity,

corrosive and abrasive media can be offered. Standard

designs include screwed wells as per API standard screw

threads, weld -in wells for directly welding on process

equipment and flanged wells with flanges as per

standards.

|

|

|

|

|

|

|